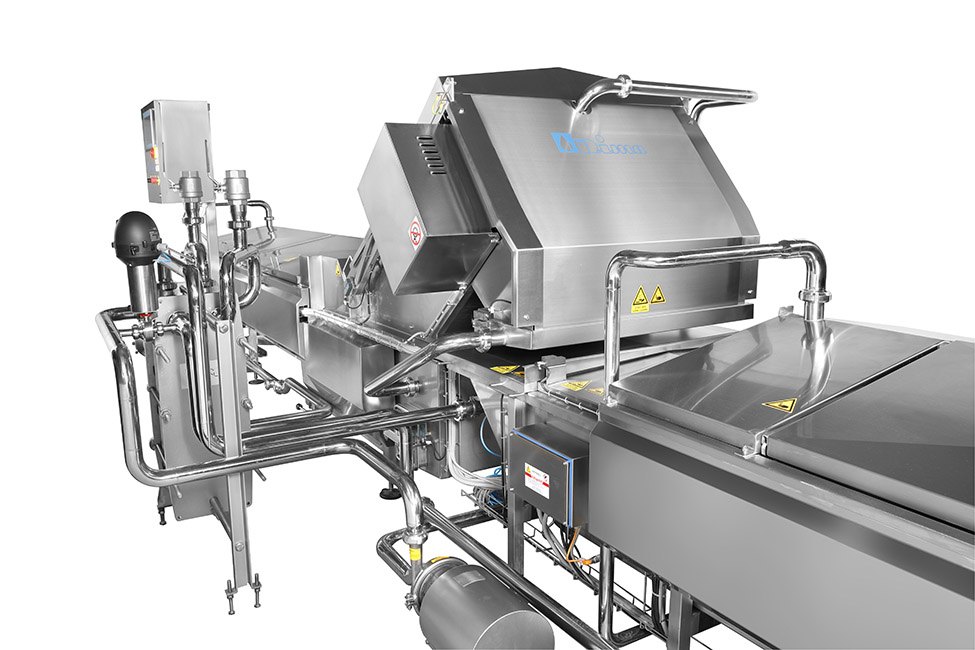

DIMA’s automatic cooling and hardening line for cooling and hardening of mozzarella, pizza-cheese and “pasta filata” stretched cheese of any type. The “HL” type vats are designed and manufactured with DIMA patented innovative system for the product advancement along the vat.

Sophisticated production solutions to fulfill all small, medium and large production capacities requirements in reliable and efficient way.

The design and execution of the DIMA cooling and hardening ensure high hygiene, perfect cleaning and gentile product handling.

Dimensions and capabilities

Customized solutions for cooling and hardening of any size of mozzarella cheese and for any production capacity requested.

The dimensions (width and length) of the cooling vats depends and always designed based on the product size, dimensions and the required production capacity to achieve.

Various configurations of design are available, specifically studied to comply with the Customer’s requirements, possible space limit and the cheese production efficiency:

- Linear straight shape

- “L” shape

- “U” shape

- “Snake” shape

- Overlap double level

- Perfect solution for industrial productions

- High production rate, flexibility and excellent proven performance

- Modular construction of unique piece of vat (no flanges)

- Fully automatic system (no manual handling of the product)

- The bottom of the cooling vat is inclined towards the outlet to allow complete discharging and higher cleaning efficiency

- The product transport cages can move vertically or horizontally

- The movement itself of the transport cages is studied to improve and optimize the efficiency the heat exchange between the cooling water and cheese

- The speed of the product advancing along the vat and therefore the permanence time of the mozzarella in the hardening line is adjustable as per production requirements

- Possibility to stop the product advancement without any risk of product accumulation or damage (squeezing)

- The water flow into the vat expressly studied in a way to avoid thermal shocks, such to cause peeling and damage to the structure of the mozzarella.

- Cooling water re-circulation for optimizing the product cooling in respect of the media and energy saving

- Adjustable and automatic thermo-regulation of the cooling water

- Product extracting station conveyor USDA approved and certified for the use in the food industry

- Possibility to integrate in the same line a pre-cooling / pre-hardening vat upstream to increase the cooling efficiency and quality.

- Control panel for the automatic control PLC with touch screen HMI.

- Automatic C.I.P. cleaning

- Mozzarella pre-cooling / pre-hardening vat upstream

- Plate heat exchanger for water cooling at service of the vat with single or double cooling section